Wrap-U-ezee Slide-In | application aid for vehicle body parts S

- Article no: YT21WUEIS01

- EAN: 4255718614018

- Hersteller: Yellotools GmbH

- Gewicht: 0,54 kg

Wrap car parts quickly and easily with Yellotools!

With Wrap-U-ezee Slide-in, Yellotools turns car wrapping upside down: Instead of pulling the wrapping aid with the pre-tensioned film over the component, the component can also be dipped into the film, right? The answer is: Yes, that's possible ;-)

It all started with the question of how to wrap a dismounted door handle, mirror housing or GPS antenna without stressing the film in the wrong places. What is already possible with the Wrap-U-ezee for attached exterior mirrors - the application of the film with optimal distribution of the tensional forces - should also work for the aforementioned small parts...

Table-mounted car wrapping aid: Just dip it!

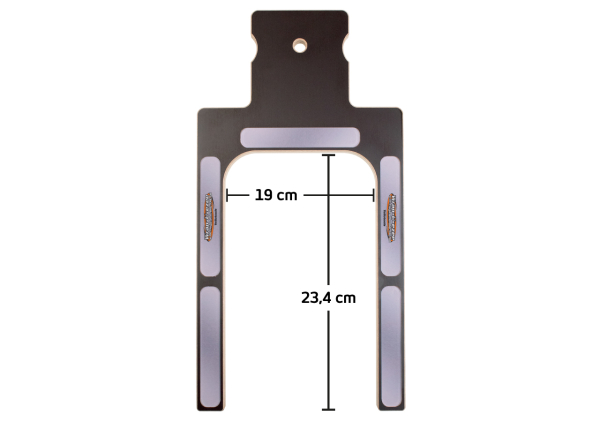

The result of these ideas is Wrap-U-ezee Slide-in, which works by following a simple principle: The film holder with the pre-tensioned vinyl is pushed horizontally into its attachment, then the component can be dipped into and finalized. Be it door handles, mirror caps or motorbike trim parts: With three different size variants, the wrapping of add-on parts is significantly simplified. The vinyl film adheres evenly in this process, which prevents partial overstretching. In addition, the highest tack load is no longer concentrated at the edges of the component; instead, the adhesive force is distributed over the entire surface.

Wrap-U-ezee Slide-in can be used as part of the YelloPEG system or "solo" by using the tabletop mount.

Product features

- wrapping frame for dismounted vehicle parts

- simple operation according to the immersion bath principle

- uniform, consistent adhesion of the vinyl

- available in three sizes (S / M / L)

- material: wood

Yellotools - Innovation for signmaking and car wrapping